Core Advantages:

1. Ultra-Fast Deployment. The plant is factory-built, tested, and pre-commissioned. This slashes project timelines from months to weeks. Upon arrival, the unit only requires placement, basic utility connections, and minimal site preparation to become operational.

2. Complete Plug-and-Play Solution. Every component is integrated within a secure containerized enclosure. This includes biological treatment, clarification, filtration, disinfection, and controls. It arrives as a single, turnkey system ready for immediate operation.

3. Unmatched Mobility and Flexibility. Standard container dimensions ensure easy transport by truck, ship, or rail to any site. The system can be relocated with minimal effort as project needs change, protecting your investment for the long term.

4. Superior Treatment Performance. Engineered for efficiency, the plant effectively removes BOD, COD, TSS, nutrients, and pathogens. It consistently produces effluent that meets strict environmental discharge standards or qualifies for safe reuse applications.

5. Significant Space Savings. The compact containerized design consolidates an entire treatment process into a minimal footprint. This is ideal for densely populated urban sites, locations with difficult terrain, or facilities where space is extremely valuable.

6. Reduced Capital and Operational Costs. Eliminates the high cost of concrete structures and extensive civil engineering. Operational expenses are minimized through automated controls, energy-efficient equipment, and low sludge production.

Key Product Features:

1. Robust Containerized Housing. Constructed from high-grade, corrosion-resistant steel for durability in harsh environments and long-term outdoor exposure.

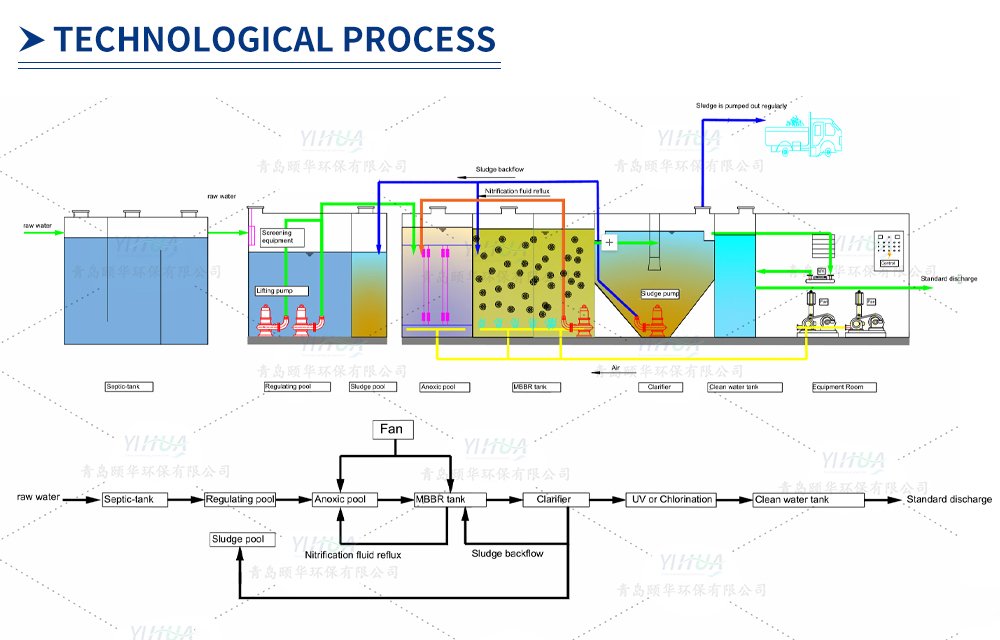

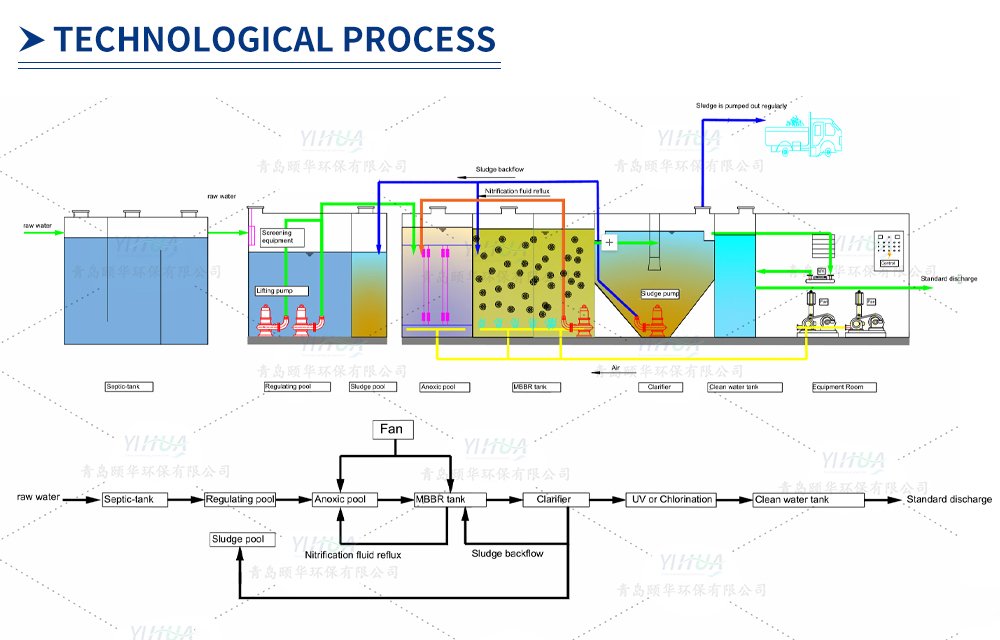

2. Flexible Process Technology. Configurable with advanced biological processes like MBBR or MBR, or conventional activated sludge, tailored to specific effluent quality goals.

3. Comprehensive Treatment Stages. Integrates all necessary steps including screening, equalization, biological treatment, clarification, disinfection, and sludge handling.

4. Fully Automated Control System. Features remote monitoring and control capabilities for real-time performance tracking, alerts, and adjustments, minimizing onsite staffing needs.

5. Energy-Efficient Design. Utilizes high-efficiency blowers, pumps, and aerators to reduce power consumption and operating costs.

6. Minimal Sludge Production. Optimized biological processes extend sludge age, reducing the volume of waste for disposal.

7. Scalable Modular Design. Treatment capacity can be easily increased by connecting additional containerized units in parallel.

Ideal Usage Scenarios:

1. Remote Communities and Mining Camps. Providing immediate, effective sanitation infrastructure where no sewage system exists.

2. Construction Site Camps. Managing wastewater for temporary worker accommodations and demobilizing easily upon project completion.

3. Resorts and Island Developments. Enabling environmentally sensitive treatment and water reuse without spoiling natural landscapes.

4. Industrial Facilities. Offering a standalone pretreatment or full treatment solution for specific process waste streams.

5. Military Base Operations and Disaster Relief. Delivering rapid, secure, and reliable wastewater treatment capacity in critical situations.

6. Urban Redevelopment Projects. Providing temporary treatment during construction or permanent solutions where space is severely limited.

7. Event Venues and Festival Sites. Managing sanitary wastewater for large temporary gatherings effectively.

8. Municipal Plant Overload or Emergency Backup. Serving as a rapid-response solution during plant upgrades, emergency repairs, or peak flow events.

Why Choose Our Containerized WWTP?

Solve your wastewater challenges with unmatched speed, flexibility, and reliability. Our Containerized WWTP delivers a complete, high-performance treatment plant in a movable box. Drastically reduce construction time and costs, ensure regulatory compliance anywhere, and gain the freedom to relocate your asset as needed. Achieve water security and environmental protection with a smart, scalable, and self-contained solution. Is your project ready for a faster, simpler approach to treatment.

Model | Capacity(m³/d) | Dimensionns(m) | Installed power (KW) | Water inlet (DN) | Water outlet (DN) | Weight(T) | Occupied area(m)² |

L | W | H |

YHWS-10 | 10 | 3.8 | 1.5 | 2 | 2.5 | 50 | 50 | 2.5 | 5.7 |

YHWS-25 | 25 | 5.6 | 2 | 2 | 3.5 | 80 | 80 | 3.8 | 11.2 |

YHWS-50 | 50 | 7.4 | 2 | 2.5 | 4.6 | 6.3 | 14.8 |

YHWS-75 | 75 | 11.5 | 2 | 2.5 | 6.1 | 7.8 | 23 |

YHWS-100 | 100 | 13.7 | 2 | 2.5 | 6.9 | 100 | 100 | 10.9 | 27.4 |

YHWS-150 | 150 | 13.4 | 3 | 3 | 7.7 | 15.1 | 40.2 |

YHWS-200 | 200 | 17.2 | 3 | 3 | 13.5 | 18 | 51.6 |

YHWS-300 | 300 | 27.4 | 3 | 3.2 | 16.5 | 150 | 150 | 26.5 | 82.2 |

YHWS-500 | 500 | 41.5 | 3 | 3.2 | 25.2 | 200 | 200 | 37.9 | 124.5 |

YHWS-1000 | 1000 | 69 | 3 | 3.5 | 38.7 | 250 | 250 | 66.2 | 207 |