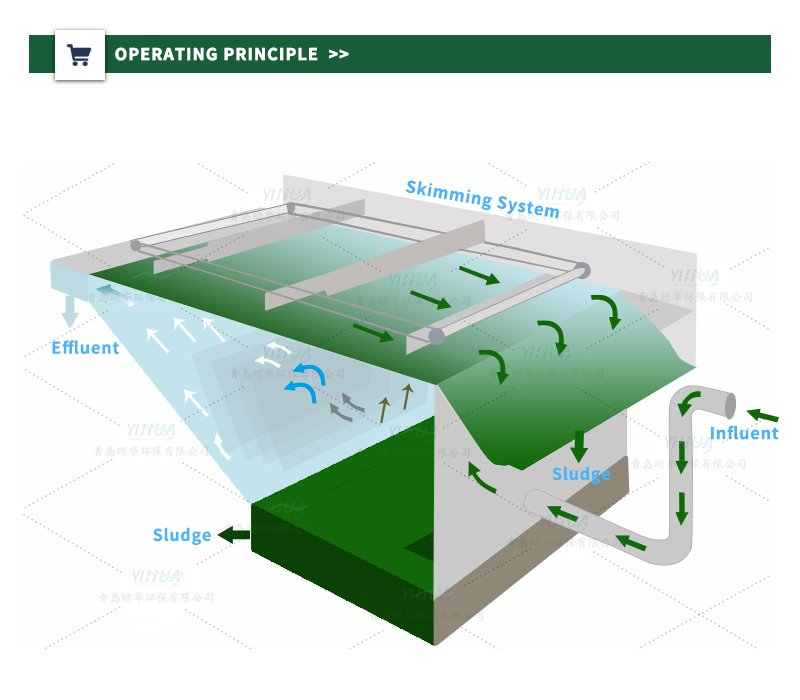

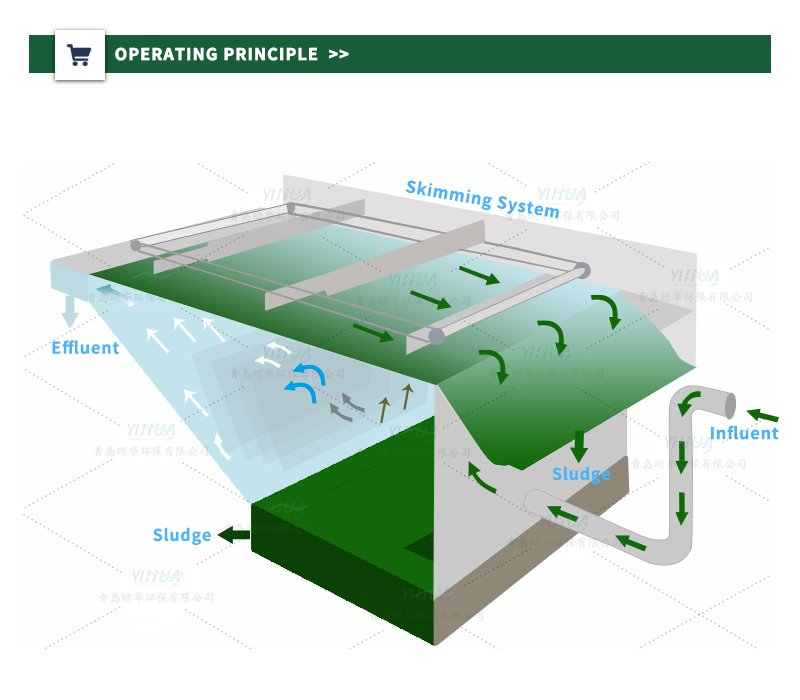

Efficient removal of suspended solids, grease, colloids, and other light pollutants is critical for industrial wastewater treatment to meet discharge and reuse standards. The Deep Exploration Dissolved Air Flotation system delivers exceptional separation efficiency and reliable performance, making it the preferred solution for global industry leaders. We provide comprehensive equipment and technical support for your water purification objectives.

Key Advantages

1.Efficient Separation, Clear Water

Fine bubbles (typically 20-100 microns) adhere to pollutants, forming fast floating bubble particle complexes

Exceptional removal rates: Achieves 90-99% removal of suspended solids, grease, colloids, and fibers

Reduces downstream treatment loads including biological processes

Short hydraulic retention time with compact footprint

2.Stable Operation, Strong Adaptability

Precision-engineered dissolution system ensures consistent microbubble generation

Effective for oily wastewater, low-density solids, and biological flocs

Handles water quality fluctuations and shock loads

3.Energy Efficiency & Cost Reduction

Optimized system with high-efficiency pumps minimizes power consumption

Reduces chemical usage in downstream processes

High-concentration sludge (95-98% moisture) lowers disposal costs

4.Compact Design, Seamless Integration

Modular structure ideal for space-limited facilities

Integrates with biological treatment, filtration, and disinfection systems

5.Intelligent Control System

Automated PLC control for operational parameters

User friendly interface simplifies maintenance

Industry Applications

1.Food & Beverage Processing

Meat processing: Removes fats, proteins, blood residues

Dairy: Eliminates milk fats and proteins

Fruit vegetable: Removes pulp and fibers

Beverage: Treats yeast and sugar residues

2.Petrochemical & Refining

Separates free, emulsified, and suspended oils

Processes refinery wastewater and stormwater

3.Pulp & Paper Manufacturing

Whitewater recovery: Removes fibers and fillers

Pulping wastewater pretreatment

4.Metal Processing

Treats oil-contaminated metal cleaning wastewater

Processes electroplating and coating wastewater

Municipal Wastewater

Enhances primary treatment

Replaces secondary clarifiers

Sludge concentration applications

5.Specialized Industries

Textile: Removes dyes and sizing agents

Pharmaceutical: Treats fermentation residues

Landfill leachate pretreatment

Marine oily wastewater treatment

Model | Capacity (m³/h) | Piping Connections | Dimensionns(mm) |

Inlet | Effluen | Sludge | Vent | L | L1 | W1 | W2 | H1 | H |

YHDAF-003 | 3 | DN40 | DN50 | DN100 | DN50 | 4300 | 3300 | 800 | 700 | 1900 | 2300 |

YHDAF-005 | 5 | DN40 | DN50 | DN100 | DN50 | 4500 | 3500 | 100 | 700 | 2000 | 2300 |

YHDAF-010 | 10 | DN50 | DN80 | DN100 | DN80 | 5600 | 4500 | 1200 | 700 | 2000 | 2300 |

YHDAF-015 | 15 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1500 | 700 | 2000 | 2300 |

YHDAF-020 | 20 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1800 | 700 | 2000 | 2300 |

YHDAF-030 | 30 | DN80 | DN100 | DN150 | DN80 | 7100 | 6000 | 2000 | 700 | 2000 | 2300 |

YHDAF-040 | 40 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2200 | 700 | 2000 | 2300 |

YHDAF-050 | 50 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2700 | 700 | 2000 | 2300 |

YHDAF-060 | 60 | DN150 | DN200 | DN150 | DN80 | 9100 | 8000 | 2800 | 700 | 2000 | 2300 |

YHDAF-070 | 70 | DN150 | DN200 | DN150 | DN80 | 10100 | 9000 | 3000 | 700 | 2000 | 2300 |

YHDAF-080 | 80 | DN150 | DN200 | DN150 | DN100 | 11100 | 10000 | 3200 | 700 | 2000 | 2300 |

YHDAF-090 | 90 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3200 | 700 | 2000 | 2300 |

YHDAF-100 | 100 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3600 | 700 | 2000 | 2300 |

YHDAF-150 | 150 | DN200 | DN250 | DN300 | DN100 | 14500 | 13400 | 3600 | 700 | 2400 | 2700 |

YHDAF-200 | 200 | DN200 | DN250 | DN300 | DN100 | 18900 | 17800 | 3600 | 700 | 2400 | 2700 |