Core Advantages:

1. Superior Removal Efficiency. Excellently removes lightweight particles, colloidal matter, fibers, fats, oils, and greases that are difficult to settle. Achieves high removal rates for suspended solids, turbidity, and BOD, producing a clarified effluent.

2. High Surface Loading Rates. Operates at significantly higher hydraulic rates than conventional clarifiers. This allows for a much smaller physical footprint, reducing space requirements and construction costs.

3. Rapid Treatment Process. The flotation process is fast, reducing hydraulic retention time. This enables quicker treatment response and a more compact plant design.

4. Thickened Sludge Production. Generates a consistently thickened sludge with higher solids concentration. This reduces sludge volume, lowering subsequent handling and disposal costs.

5. Flexible and Controllable Operation. The recycle flow and air-to-solids ratio can be easily adjusted. This allows for optimized performance to handle fluctuations in flow and influent loadings.

6. Proven Chemical Integration. Works seamlessly with coagulants and flocculants to enhance aggregation and capture of fine particles, ensuring maximum treatment efficiency.

Key Product Features:

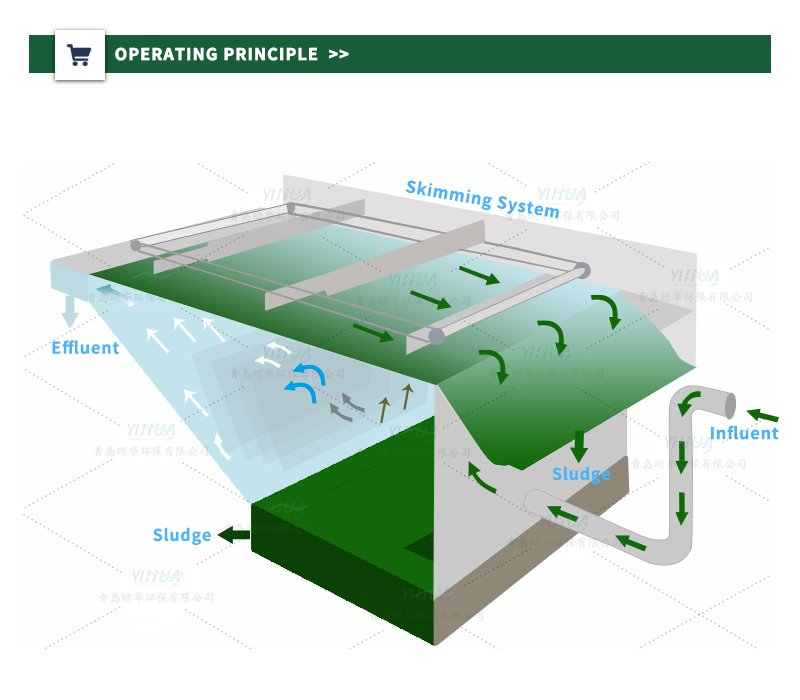

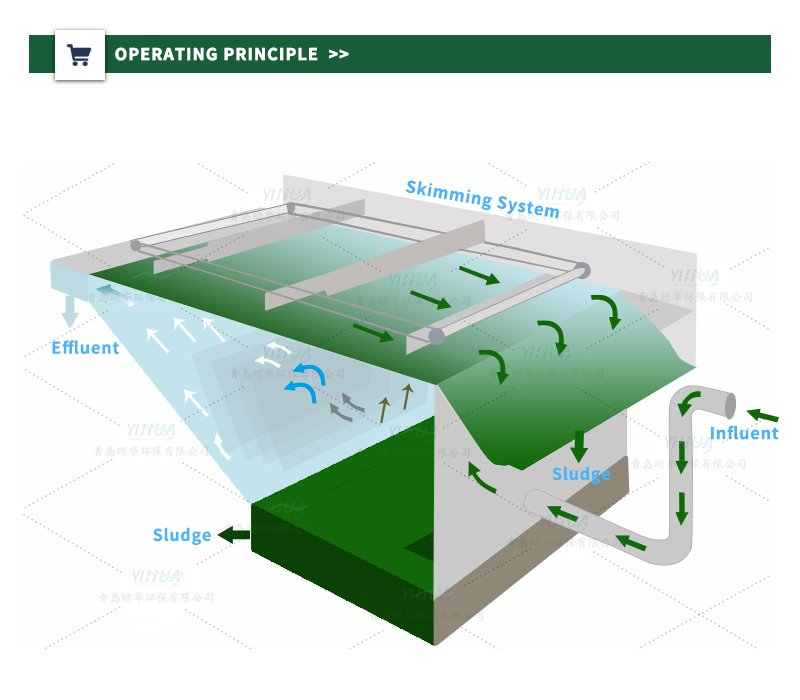

1. Efficient Saturation System. A robust pressure vessel designed to efficiently dissolve air into the recycle stream under pressure, creating a dense cloud of micro-sized bubbles for effective flotation.

2. Precision Release Mechanism. Features specially designed nozzles or a needle valve to efficiently release the pressurized recycle flow into the flotation tank. This ensures optimal formation of fine micro-bubbles.

3. Optimized Flotation Tank. Engineered with a stilling zone for laminar flow and a specially configured surface skimming system for continuous removal of the floated sludge blanket.

4. Full-Scrape Surface Skimmer. A reliable mechanical skimmer continuously removes the thickened froth and floated sludge from the water surface.

5. Bottom Scraper Assembly. Optional bottom rakes assist in gathering any settled heavy solids for periodic removal.

6. Integrated Chemical Conditioning. Includes points for the precise dosing of coagulants and flocculants to precondition the wastewater and improve floc formation and bubble attachment.

7. Automated Controls. A control panel manages recycle pumps, air dosage, and skimmer operation for consistent performance with minimal supervision.

Ideal Usage Scenarios:

1. Industrial Wastewater Treatment. Essential for oil refineries, petrochemical plants, meat processing and poultry plants, dairy and food processing facilities, and paper mills.

2. Potable Water Treatment. Used for algae and natural color removal in surface water treatment plants.

3. Sludge Thickening. Highly effective for thickening biological sludges from activated sludge processes, reducing volume before digestion or dewatering.

4. Product Recovery. Valuable for recovering raw material solids like protein or fiber from certain industrial process streams.

5. Pretreatment for Membrane Systems. Protects downstream ultrafiltration and reverse osmosis membranes by removing oils and suspended solids.

6. Marine and Port Waste Reception. Treating oily wastewater from ships and port facilities.

Why Choose Our Dissolved Air Flotation Plant?

Tackle your most difficult clarification challenges with confidence and efficiency. Our Dissolved Air Flotation Plant delivers unmatched removal of fats, oils, greases, and lightweight solids in a compact and reliable footprint. Benefit from rapid treatment rates, thickened sludge, reduced chemical usage, and consistent high-quality effluent. It is the definitive technology for industrial pretreatment and advanced clarification where gravity is not enough.

Model | Capacity (m³/h) | Piping Connections | Dimensionns(mm) |

Inlet | Effluen | Sludge | Vent | L | L1 | W1 | W2 | H1 | H |

YHDAF-003 | 3 | DN40 | DN50 | DN100 | DN50 | 4300 | 3300 | 800 | 700 | 1900 | 2300 |

YHDAF-005 | 5 | DN40 | DN50 | DN100 | DN50 | 4500 | 3500 | 100 | 700 | 2000 | 2300 |

YHDAF-010 | 10 | DN50 | DN80 | DN100 | DN80 | 5600 | 4500 | 1200 | 700 | 2000 | 2300 |

YHDAF-015 | 15 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1500 | 700 | 2000 | 2300 |

YHDAF-020 | 20 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1800 | 700 | 2000 | 2300 |

YHDAF-030 | 30 | DN80 | DN100 | DN150 | DN80 | 7100 | 6000 | 2000 | 700 | 2000 | 2300 |

YHDAF-040 | 40 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2200 | 700 | 2000 | 2300 |

YHDAF-050 | 50 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2700 | 700 | 2000 | 2300 |

YHDAF-060 | 60 | DN150 | DN200 | DN150 | DN80 | 9100 | 8000 | 2800 | 700 | 2000 | 2300 |

YHDAF-070 | 70 | DN150 | DN200 | DN150 | DN80 | 10100 | 9000 | 3000 | 700 | 2000 | 2300 |

YHDAF-080 | 80 | DN150 | DN200 | DN150 | DN100 | 11100 | 10000 | 3200 | 700 | 2000 | 2300 |

YHDAF-090 | 90 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3200 | 700 | 2000 | 2300 |

YHDAF-100 | 100 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3600 | 700 | 2000 | 2300 |

YHDAF-150 | 150 | DN200 | DN250 | DN300 | DN100 | 14500 | 13400 | 3600 | 700 | 2400 | 2700 |

YHDAF-200 | 200 | DN200 | DN250 | DN300 | DN100 | 18900 | 17800 | 3600 | 700 | 2400 | 2700 |