Our DAF system is well-designed and mature in technology. Its processing capacity covers 3 m³/h to 500 m³/h and larger scales. It is an ideal choice for solving various oily and suspended wastewater treatment problems.

Excellent separation efficiency:

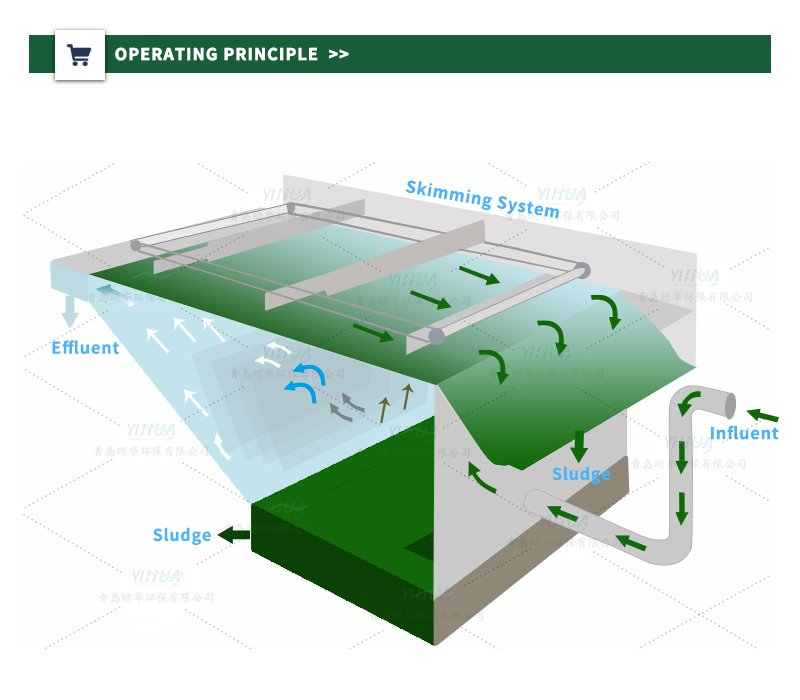

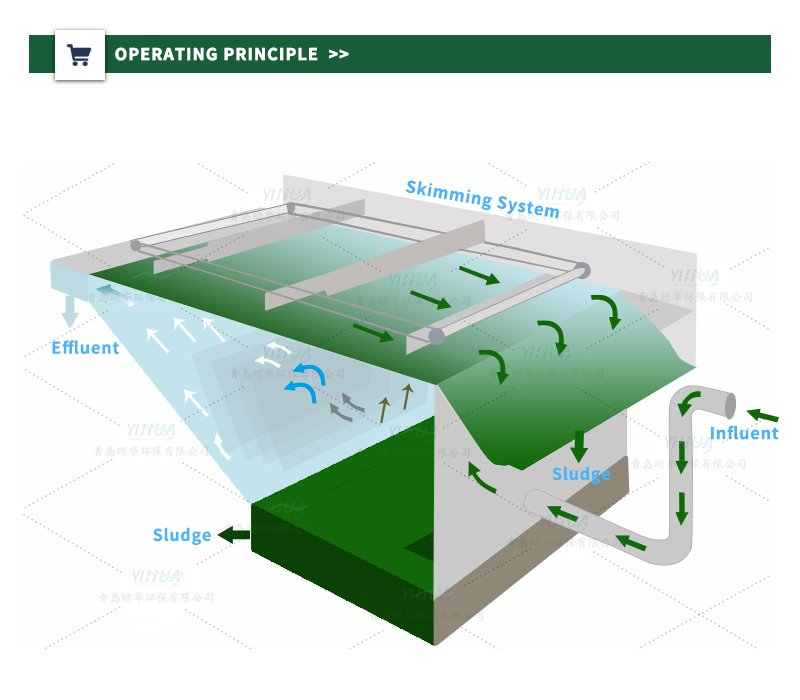

Adopting advanced microbubble generation technology, a large number of stable and fine microbubbles are generated, providing a huge specific surface area, significantly improving the capture rate and floating speed of pollutants.

High removal rate: It has a significant effect on the removal of pollutants such as SS, grease, BOD, COD, etc., and is particularly good at treating light suspended solids that are difficult to treat by traditional sedimentation methods.

Stable and reliable operation:

Core components dissolved air tank, releaser, scraper, etc. are made of high-quality stainless steel or high-strength anti-corrosion materials, which are durable and adaptable to complex water quality environments.

Modular design, compact and reasonable structure, convenient installation and maintenance, low system failure rate, and long-term stable operation.

Intelligent automatic control:

Standard PLC intelligent control system can monitor key parameters such as dissolved air pressure, water level, and scum thickness in real time.

It realizes functions such as automatic slag discharge, automatic backwashing, and operation status alarm, greatly reducing the intensity of manual operation and ensuring stable treatment effect.

Significant energy saving and consumption reduction:

The optimized dissolved air system and high-efficiency circulation pump maximize the air dissolution efficiency and reduce energy consumption.

Compared with other deep treatment processes, DAF systems usually have lower operating costs and chemical agent consumption especially when used as pretreatment or core treatment units.

Compact footprint:

Compared with traditional sedimentation tanks, DAF systems have higher hydraulic loads and sludge loads. Under the premise of achieving the same or even better treatment effect, the required footprint is smaller, which is especially suitable for projects with limited sites.

Wide adaptability:

It can flexibly adapt to different water quality and treatment requirements by adjusting the dissolved air pressure, reflux ratio, adding appropriate amount of coagulant flocculant PAC PAM, etc.

It is an ideal pretreatment unit reducing the subsequent biochemical treatment load or deep treatment unit ensuring that the final effluent meets the standards.

Model | Capacity (m³/h) | Piping Connections | Dimensionns(mm) |

Inlet | Effluen | Sludge | Vent | L | L1 | W1 | W2 | H1 | H |

YHDAF-003 | 3 | DN40 | DN50 | DN100 | DN50 | 4300 | 3300 | 800 | 700 | 1900 | 2300 |

YHDAF-005 | 5 | DN40 | DN50 | DN100 | DN50 | 4500 | 3500 | 100 | 700 | 2000 | 2300 |

YHDAF-010 | 10 | DN50 | DN80 | DN100 | DN80 | 5600 | 4500 | 1200 | 700 | 2000 | 2300 |

YHDAF-015 | 15 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1500 | 700 | 2000 | 2300 |

YHDAF-020 | 20 | DN50 | DN100 | DN150 | DN80 | 6100 | 5000 | 1800 | 700 | 2000 | 2300 |

YHDAF-030 | 30 | DN80 | DN100 | DN150 | DN80 | 7100 | 6000 | 2000 | 700 | 2000 | 2300 |

YHDAF-040 | 40 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2200 | 700 | 2000 | 2300 |

YHDAF-050 | 50 | DN100 | DN150 | DN150 | DN80 | 8100 | 7000 | 2700 | 700 | 2000 | 2300 |

YHDAF-060 | 60 | DN150 | DN200 | DN150 | DN80 | 9100 | 8000 | 2800 | 700 | 2000 | 2300 |

YHDAF-070 | 70 | DN150 | DN200 | DN150 | DN80 | 10100 | 9000 | 3000 | 700 | 2000 | 2300 |

YHDAF-080 | 80 | DN150 | DN200 | DN150 | DN100 | 11100 | 10000 | 3200 | 700 | 2000 | 2300 |

YHDAF-090 | 90 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3200 | 700 | 2000 | 2300 |

YHDAF-100 | 100 | DN150 | DN200 | DN150 | DN100 | 11600 | 10500 | 3600 | 700 | 2000 | 2300 |

YHDAF-150 | 150 | DN200 | DN250 | DN300 | DN100 | 14500 | 13400 | 3600 | 700 | 2400 | 2700 |

YHDAF-200 | 200 | DN200 | DN250 | DN300 | DN100 | 18900 | 17800 | 3600 | 700 | 2400 | 2700 |