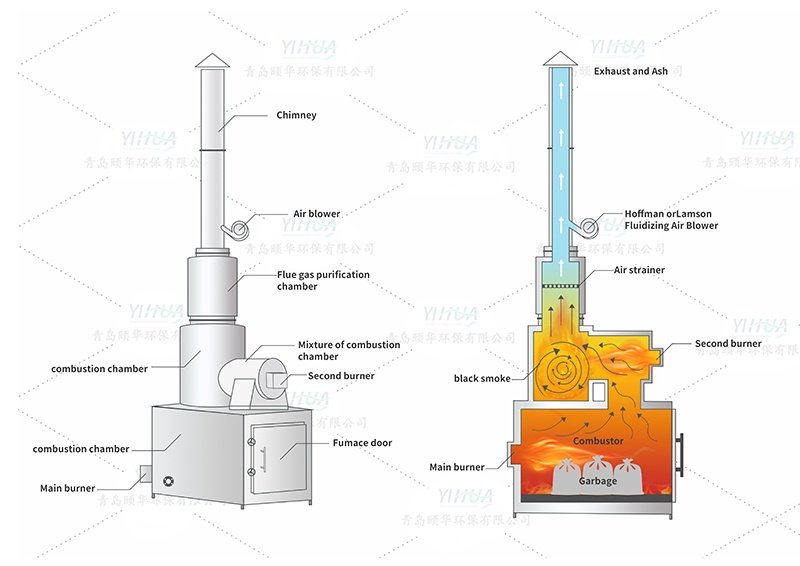

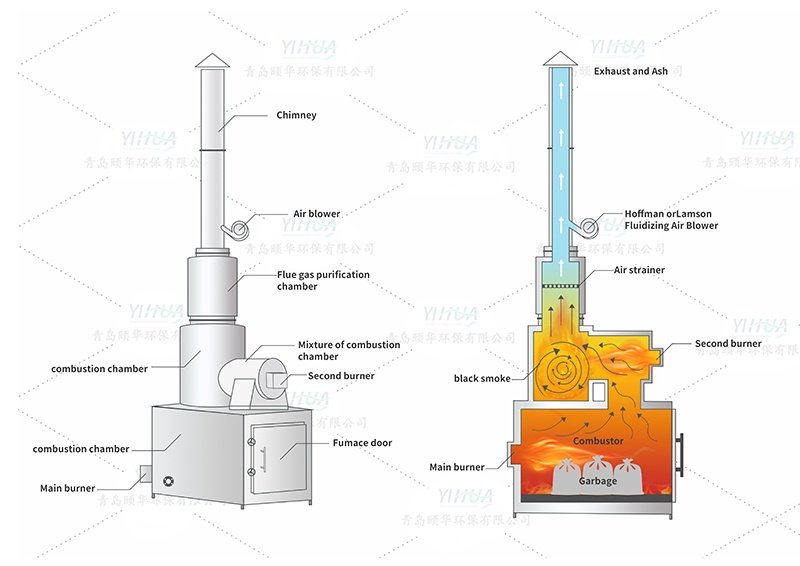

Our advanced 316 stainless steel waste incinerator delivers high-efficiency, eco-friendly disposal for a wide spectrum of waste streams. Engineered with premium corrosion-resistant materials, it ensures complete combustion of municipal, medical, and industrial waste through high-temperature incineration technology. An integrated flue gas purification system—comprising cyclone, scrubber, and bag filter stages—guarantees emissions that comply with stringent international environmental standards. Third-party emission test reports are provided to ensure transparency and simplify regulatory compliance.

Key Benefits

316 Stainless Steel Construction

Boasts superior resistance to high temperatures and corrosion, significantly extending the equipment’s service life even under continuous, demanding operations.

Wide Waste Compatibility

Capable of safely processing general solid waste, infectious medical waste, hazardous materials, and industrial by-products without requiring pre-sorting—improving operational flexibility and throughput.

Emission Compliance Guaranteed

A multi-stage gas cleaning system effectively reduces particulate matter, dioxins, furans, acidic gases, and heavy metals, maintaining all outputs below internationally regulated limits.

Third-Party Test Reports

Official emission certification from accredited laboratories is available, streamlining environmental audits and legal compliance in various markets.

Applications

Municipalities & Rural Areas: Enables centralized solid waste management with minimized transport costs and landfill reliance.

Healthcare Facilities: Ensures secure, high-temperature disposal of biomedical waste, mitigating contamination and infection risks.

Industrial Zones & Factories: Delivers efficient reduction of industrial by-products with up to 90% volume reduction, supporting cleaner production processes.

Why Choose Us?

20+ Years Expertise

We specialize in the R&D and manufacturing of eco-incineration systems, offering customized engineering solutions tailored to varying waste profiles and local regulations.

End-to-End Service

Comprehensive support covers site assessment, installation, operator training, and ongoing maintenance—ensuring smooth operation and longevity.

500+ Successful Projects

Globally trusted by municipalities, hospitals, and industrial operators for reliable performance, durability, and environmentally sound waste disposal.

Name | YHIA-50 | YHIA-100 | YHIA-200 | YHIA-300 | YHIA-500 |

Dimensions | 1400*1000*2100mm(L*W*H) | 1500*1100*2200mm(L*W*H) | 2000*1300*2600mm(L*W*H) | 2500*1400*2400mm(L*W*H) | 2900*1800*2800mm(L*W*H) |

Garbage entrance size | 1100*500*500mm(L*W*H) | 1200*600*500mm(L*W*H) | 1400*800*700mm(L*W*H) | 1800*900*900mm(L*W*H) | 2300*1200*900mm(L*W*H) |

Incineration capacity | 30~50kg/h | 80~100kg/h | 150~200kg/h | 300~400kg/h | 500~600kg/h |

Induced draft fan | 0.75KW | 0.75KW | 0.75KW | 3 KW | 3 KW |

Burner | 2 sets | 3sets |

Voltage | 220V/380V |

Fuel | Diesel fuel |

Fuel consumption per hour | 4~6L/H | 5~8 L/h | 20~30 L/h | ~40 L/H | 30~40 L/H |

Total power | 1.5KW | 1.5KW | 1.8KW | 4 KW | 4 KW |

Feeding method | manual |

Ignition method | automatic |

Incineration temperature | Main combustion chamber 600~800 degrees, secondary combustion chamber 900~1100 degrees |

Floor space | 2.5*3m | 2.5*3m | 4*6m | 5*3m | 6*4m |

Material | Shell: Welded steel plate. Firewall: monolithic prefabrication of refractory bricks and refractory concrete |

Chimney | 3m | 6m |

Weight | 2100kg | 2500kg | 3200kg | 4600kg | 6500kg |