Achieve superior solid-liquid separation with maximum space savings. Our Lamella Settler utilizes inclined plate technology to dramatically enhance settling efficiency within a compact footprint. It is the proven solution for effective clarification and thickening across diverse water and wastewater treatment applications, delivering consistent performance with minimal energy requirements.

Core Advantages:

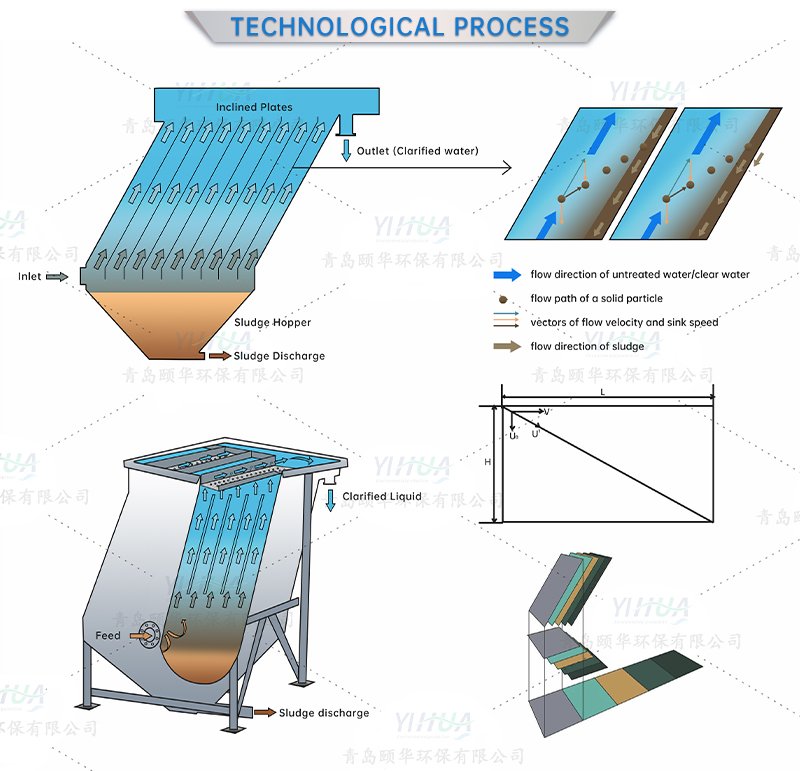

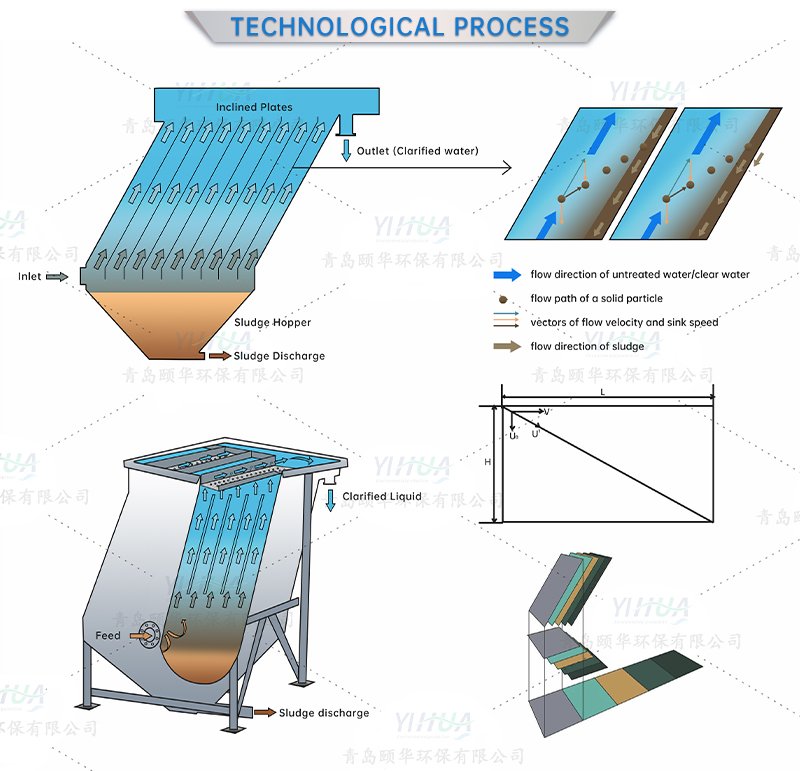

1.Unmatched Space Efficiency.

The unique inclined plate design multiplies effective settling area within a small physical footprint. This allows installation in tight spaces or enables higher flow capacity within existing tank structures, reducing construction costs significantly.

2.Enhanced Settling Performance.

Laminar flow conditions between plates promote rapid and efficient particle settling. Achieves excellent removal of suspended solids, turbidity, and flocculated impurities, producing clear effluent ready for further treatment or discharge.

3.Robust and Reliable Operation.

Simple gravity-driven process with no moving parts within the settling zone. Ensures dependable performance with minimal mechanical complexity, reducing maintenance needs and operational downtime.

4.High Capacity Flexibility.

Effectively handles variable flow rates and influent loadings. Design configurations adapt to peak flows and fluctuations, maintaining consistent effluent quality under challenging conditions.

5.Reduced Sludge Volume.

Improved solids concentration in the sludge hopper leads to thicker sludge. This lowers sludge handling volumes, reduces dewatering costs, and decreases disposal frequency and associated expenses.

6.Low Operating Costs.

Gravity-based separation consumes minimal energy. Combined with low maintenance requirements and reduced sludge volumes, it offers a highly cost-effective clarification solution over its long lifespan.

Key Product Features:

1.Optimized Inclined Plates.

Engineered plate angle and spacing maximize settling efficiency and solids slideability. Constructed from durable, corrosion-resistant materials like stainless steel or PVC.

2.Efficient Inlet Distribution System.

Ensures even flow distribution across the entire plate pack, preventing short-circuiting and optimizing settling conditions.

3.Effective Sludge Collection.

Strategically designed hopper or scraper system facilitates concentrated sludge removal without disturbing the settling process.

4.Clear Effluent Collection.

Efficient launders collect clarified water uniformly from the top of the plate pack.

5.Modular Construction.

Facilitates easy installation, retrofitting into existing tanks, and future expansion.

6.Versatile Design Options.

Available in various materials, plate geometries, and configurations (rectangular, circular) to suit specific application needs and tank shapes.

Ideal Usage Scenarios:

1.Municipal Wastewater Treatment Plants.

As primary or secondary clarifiers, especially in space-limited upgrades or new compact plants.

2.Drinking Water Treatment Plants.

For sedimentation of flocculated impurities like algae, silt, and coagulated particles after flocculation.

3.Industrial Process Water Treatment.

Clarifying effluent in industries like food and beverage, pulp and paper, textiles, and chemical manufacturing.

4.Mining and Mineral Processing.

Tailings dewatering, thickener overflow clarification, and process water recovery.

5.Stormwater Treatment.

Removing sediments and pollutants from runoff before discharge or reuse.

6.Sludge Thickening.

Concentrating sludge from biological treatment processes like activated sludge prior to dewatering.

7.Pre-Treatment for Filtration or Membrane Systems.

Protecting downstream processes by removing bulk solids efficiently.

8.Retrofitting Existing Clarifiers.

Boosting capacity and performance of outdated or overloaded conventional sedimentation tanks.

9.Compact Package Plants.

Integrating as the clarification stage within prefabricated or containerized treatment systems.

10.Emergency Water Treatment.

Rapid deployment units for disaster relief providing essential water clarification.

Why Choose Our Lamella Settler?

Maximize your settling performance while minimizing your footprint and operational costs. Our Lamella Settler delivers proven, reliable clarification through intelligent design. Experience significant space savings, reduced sludge volumes, low energy consumption, and consistent high-quality effluent. It is the smart, efficient choice for upgrading existing infrastructure, enabling compact new builds, and tackling demanding clarification challenges across water and wastewater treatment.

Model | Capacity (m³/h) | Dimensions(m) | List of nozzles (dn) |

L | W | H | Water inlet | Water outlet | Mud outlet |

YHLC1-001 | 1 | 1.6 | 0.8 | 2 | 25 | 50 | 50 |

YHLC1-003 | 3 | 1.6 | 1.1 | 2 | 50 | 50 | 50 |

YHLC1-005 | 5 | 2.2 | 1.4 | 2.2 | 80 | 80 | 65 |

YHLC1-010 | 10 | 3.2 | 1.8 | 3.5 | 80 | 80 | 80 |

YHLC1-020 | 20 | 3.2 | 2.2 | 3.5 | 100 | 100 | 80 |

YHLC1-030 | 30 | 4.2 | 2.2 | 4.1 | 150 | 150 | 80 |

YHLC1-040 | 40 | 5.3 | 2.2 | 3.5 | 150 | 150 | 80*2 |

YHLC1-050 | 50 | 6.3 | 2.2 | 3.9 | 150 | 200 | 80*2 |

YHLC1-060 | 60 | 7.3 | 2.2 | 3.5 | 200 | 200 | 80*3 |

YHLC1-070 | 70 | 8.8 | 2.2 | 3.9 | 200 | 200 | 80*3 |

YHLC1-080 | 80 | 9.3 | 2.2 | 3.5 | 200 | 200 | 80*4 |

YHLC1-090 | 90 | 10.2 | 2.2 | 4.1 | 200 | 250 | 80*3 |

YHLC1-100 | 100 | 11.3 | 2.2 | 3.9 | 250 | 250 | 80*4 |

YHLC1-120 | 120 | 9.3 | 3.2 | 3.5 | 250 | 250 | 80*4 |

YHLC1-150 | 150 | 11.3 | 3.2 | 3.9 | 250 | 250 | 80*4 |