Core Advantages:

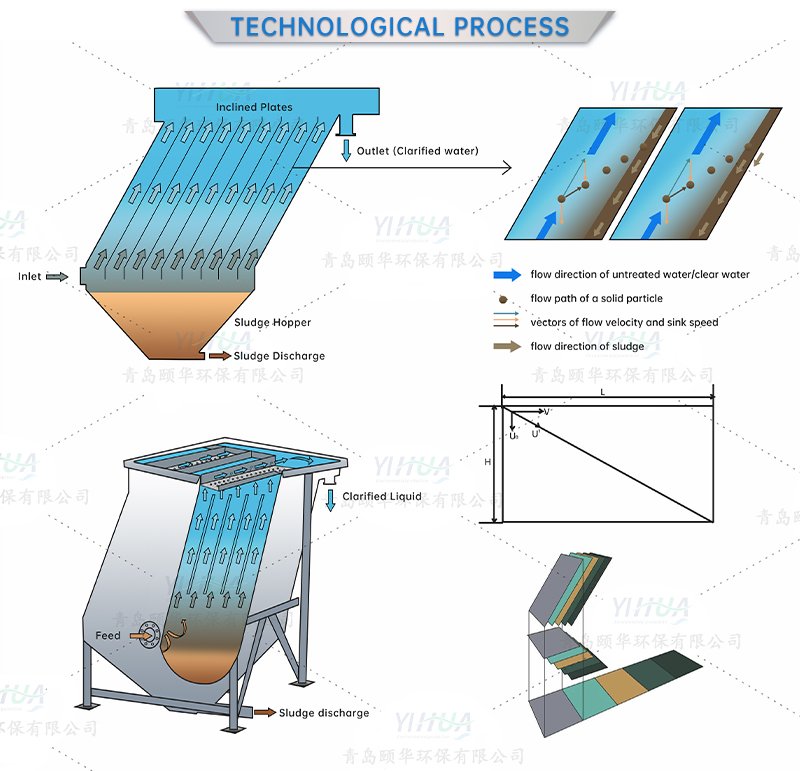

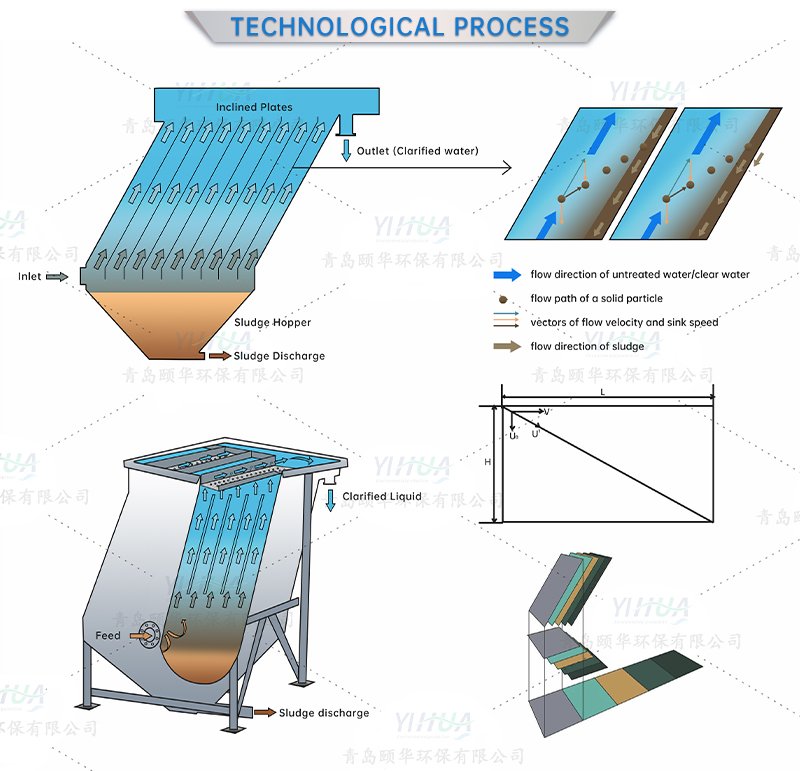

1. Exceptional Space Efficiency. The inclined plate design multiplies the effective settling surface area. This allows for a much smaller tank size compared to conventional clarifiers, drastically reducing the required installation space and civil construction costs.

2. High Rate Settling Performance. Laminar flow conditions between the plates promote rapid and efficient settling of suspended solids. This results in excellent effluent clarity with low turbidity and consistent removal of flocculated particles.

3. Proven Reliability and Simplicity. The gravity-driven process has no moving parts within the settling zone. This simple design ensures robust and dependable operation with minimal maintenance needs and very low energy consumption.

4. Effective Sludge Thickening. Solids slide down the inclined plates and compact in the sludge hopper. This process yields a thicker, more concentrated sludge which reduces the volume for further handling and lowers disposal costs.

5. Handles Flow Variations. The design is effective across a range of flow rates. It can tolerate moderate hydraulic and pollutant load fluctuations while maintaining stable treatment performance.

6. Versatile Application. Suitable for both municipal and industrial treatment processes. It performs effectively as a primary clarifier, secondary clarifier, or for water purification.

Key Product Features:

1. Optimized Plate Pack. Engineered with precise plate angle and spacing to maximize settling efficiency and ensure solids slide easily. Constructed from durable materials like stainless steel or polymer for long life.

2. Efficient Inlet System. A specially designed inlet distribution zone ensures even flow across the entire cross-section of the plate pack. This prevents short-circuiting and maximizes clarifier performance.

3. Effective Sludge Collection. A conical hopper or gentle scraper mechanism allows for the continuous or intermittent removal of concentrated sludge without disrupting the settling process.

4. Clear Effluent Collection. Effluent launders with adjustable weirs are positioned to collect clarified water from the top of each plate channel, ensuring optimal overflow rates and water quality.

5. Modular and Retrofittable Design. Units can be easily installed in new tanks or retrofitted into existing clarifiers to increase capacity and improve performance without expanding the tank footprint.

Ideal Usage Scenarios:

1. Upgrading Existing Treatment Plants. Retrofitting lamella plates into current clarifiers is a cost-effective method to increase hydraulic capacity and improve effluent quality.

2. New Compact Wastewater Treatment Plants. Ideal for space-constrained sites in urban areas or industrial facilities where footprint is a primary concern.

3. Drinking Water Treatment Plants. Used for sedimentation after flocculation to remove floc particles, turbidity, and algae from raw water.

4. Industrial Process Water and Wastewater. Clarifying effluent in industries such as mining, food and beverage, pulp and paper, and chemical production.

5. Stormwater Runoff Treatment. Removing sediments, oils, and heavy metals from stormwater before discharge or reuse.

6. Sludge Thickening Applications. Used as a dedicated unit to concentrate sludge from biological processes, reducing the volume sent to dewatering equipment.

Why Choose Our Inclined Plate Lamella Clarifier?

Maximize your clarification performance while minimizing your spatial and operational costs. Our clarifier delivers high efficiency separation through intelligent and simple design. Benefit from significant space savings, reduced sludge volumes, low energy consumption, and consistent reliable operation. It is the practical and efficient choice for enhancing clarification in both new and upgraded water and wastewater treatment systems.

Model | Capacity (m³/h) | Dimensions(m) | List of nozzles (dn) |

L | W | H | Water inlet | Water outlet | Mud outlet |

YHLC1-001 | 1 | 1.6 | 0.8 | 2 | 25 | 50 | 50 |

YHLC1-003 | 3 | 1.6 | 1.1 | 2 | 50 | 50 | 50 |

YHLC1-005 | 5 | 2.2 | 1.4 | 2.2 | 80 | 80 | 65 |

YHLC1-010 | 10 | 3.2 | 1.8 | 3.5 | 80 | 80 | 80 |

YHLC1-020 | 20 | 3.2 | 2.2 | 3.5 | 100 | 100 | 80 |

YHLC1-030 | 30 | 4.2 | 2.2 | 4.1 | 150 | 150 | 80 |

YHLC1-040 | 40 | 5.3 | 2.2 | 3.5 | 150 | 150 | 80*2 |

YHLC1-050 | 50 | 6.3 | 2.2 | 3.9 | 150 | 200 | 80*2 |

YHLC1-060 | 60 | 7.3 | 2.2 | 3.5 | 200 | 200 | 80*3 |

YHLC1-070 | 70 | 8.8 | 2.2 | 3.9 | 200 | 200 | 80*3 |

YHLC1-080 | 80 | 9.3 | 2.2 | 3.5 | 200 | 200 | 80*4 |

YHLC1-090 | 90 | 10.2 | 2.2 | 4.1 | 200 | 250 | 80*3 |

YHLC1-100 | 100 | 11.3 | 2.2 | 3.9 | 250 | 250 | 80*4 |

YHLC1-120 | 120 | 9.3 | 3.2 | 3.5 | 250 | 250 | 80*4 |

YHLC1-150 | 150 | 11.3 | 3.2 | 3.9 | 250 | 250 | 80*4 |