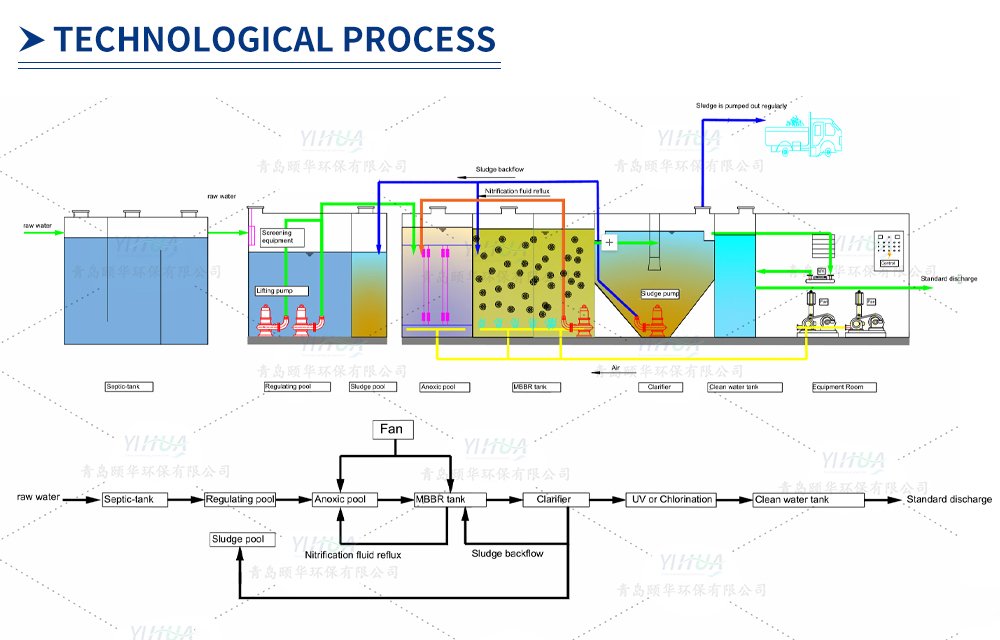

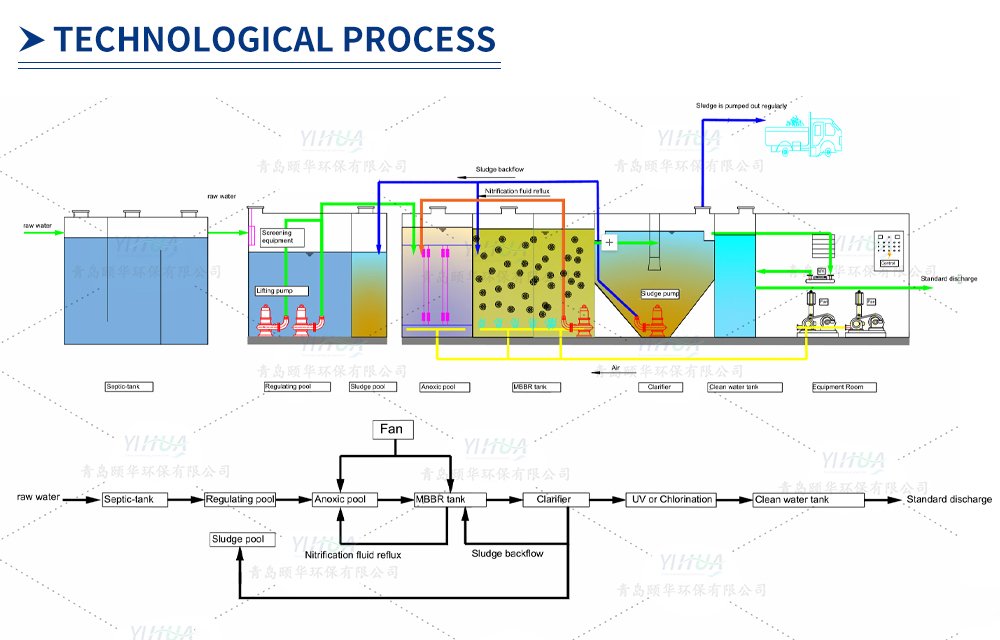

Experience the pinnacle of advanced wastewater treatment within a robust, transportable container. Our Containerized MBR Plant integrates cutting-edge Membrane Bioreactor technology into a self-contained unit, delivering exceptionally clear, reusable effluent with minimal footprint and rapid deployment. It's engineered for demanding applications where space is constrained, mobility is key, or high-quality water reuse is essential.

Core Advantages:

1.Exceptional Effluent Quality.

The heart of the system is submerged ultrafiltration membranes. They act as an absolute barrier, producing crystal clear water with near-zero suspended solids, very low turbidity, and significantly reduced pathogens. This meets the strictest standards for sensitive discharge or direct reuse.

2.True Plug-and-Play Mobility.

Housed entirely within durable, ISO-standard shipping containers. This enables easy transport by road, rail, or sea to virtually any location. Installation is drastically simplified, requiring only basic site preparation and utility connections. Ideal for remote or temporary sites.

3.Ultra-Compact Footprint.

The highly efficient MBR process and containerized design achieve maximum treatment capacity within the absolute minimal space. It eliminates the need for large concrete tanks or extensive civil works, solving critical space limitations.

4.Guaranteed Compliance and Reuse Ready.

Consistently achieves effluent quality exceeding stringent local and international discharge regulations. The high-grade output is directly suitable for non-potable reuse applications, conserving valuable freshwater resources.

5.Rapid Deployment and Scalability.

Units are factory-assembled, tested, and pre-commissioned. Dramatically reduces installation time from months to weeks. Future capacity increases are straightforward by adding more containerized modules.

6.Robust and Reliable Construction.

Built using high-grade corrosion-resistant materials like stainless steel and reinforced composites. Engineered for long-term durability and reliable operation in harsh environments with minimal maintenance downtime.

Key Product Features:

1.Advanced MBR Technology.

Submerged hollow-fiber or flat-sheet ultrafiltration membranes integrated directly within the biological reactor.

2.Superior Treatment Performance.

Achieves outstanding removal of BOD, COD, TSS, ammonia, nitrogen, and pathogens. Effluent turbidity typically less than 0.2 NTU.

3.Fully Automated Operation.

Sophisticated control system with remote monitoring and alarm capabilities. Minimizes operator intervention.

4.Optimized Energy Efficiency.

High-efficiency blowers and energy-saving membrane scouring systems reduce operational costs.

5.Low Sludge Production.

Extended sludge age within the MBR process reduces sludge volumes and disposal frequency compared to conventional treatment.

6.Simplified Maintenance.

Designed for accessibility within the container. Features automated membrane cleaning systems.

Ideal Usage Scenarios:

1.Remote Communities & Islands. Providing advanced treatment where conventional infrastructure is impractical or too costly.

2.Resorts, Hotels & Eco-Lodges. Ensuring environmental compliance and enabling landscape irrigation reuse in sensitive locations.

3.Industrial Camps & Mining Sites. Rapid deployment for temporary or permanent worker accommodations in challenging environments.

4.Construction Sites. Meeting temporary wastewater treatment needs for large projects.

5.Military Bases & Disaster Relief. Providing critical, mobile sanitation and water reuse capabilities rapidly.

6.Urban Redevelopment & Space-Constrained Sites. Fitting treatment into tight spaces where land is expensive or unavailable.

7.Water Reuse Projects. Direct source of high-quality water for toilet flushing, cooling towers, vehicle wash, or irrigation where potable water conservation is vital.

Model | Capacity(m³/d) | Dimensionns(m) | Installed power (KW) | Water inlet (DN) | Water outlet (DN) | Weight(T) | Occupied area(m)² |

L | W | H |

YHWS-10 | 10 | 3.8 | 1.5 | 2 | 2.5 | 50 | 50 | 2.5 | 5.7 |

YHWS-25 | 25 | 5.6 | 2 | 2 | 3.5 | 80 | 80 | 3.8 | 11.2 |

YHWS-50 | 50 | 7.4 | 2 | 2.5 | 4.6 | 6.3 | 14.8 |

YHWS-75 | 75 | 11.5 | 2 | 2.5 | 6.1 | 7.8 | 23 |

YHWS-100 | 100 | 13.7 | 2 | 2.5 | 6.9 | 100 | 100 | 10.9 | 27.4 |

YHWS-150 | 150 | 13.4 | 3 | 3 | 7.7 | 15.1 | 40.2 |

YHWS-200 | 200 | 17.2 | 3 | 3 | 13.5 | 18 | 51.6 |

YHWS-300 | 300 | 27.4 | 3 | 3.2 | 16.5 | 150 | 150 | 26.5 | 82.2 |

YHWS-500 | 500 | 41.5 | 3 | 3.2 | 25.2 | 200 | 200 | 37.9 | 124.5 |

YHWS-1000 | 1000 | 69 | 3 | 3.5 | 38.7 | 250 | 250 | 66.2 | 207 |