In livestock operations, veterinary clinics, or pet cremation services, the safe and compliant disposal of animal remains is a critical task. Our next-generation Animal Incinerator represents the ultimate solution, combining cutting-edge technology with rugged design. It is engineered to transform biological waste into sterile ash in the most responsible manner, eliminating your concerns and safeguarding our shared environment.

Our Animal Incinerator is designed for the following key scenarios and industries:

1. Livestock and Farms: Efficiently handle poultry, pigs, sheep, and other livestock culled due to disease, natural disasters, or normal culling, preventing the spread of disease and ensuring the health of surviving animals.

2. Veterinary Hospitals and Clinics: Provide humane, respectful, and hygienic care for deceased pets, maintaining a sterile and safe medical environment.

3. Pet Cremation and Funeral Services: Provide professional, respectful, and personalized cremation services for pet owners, meeting both emotional and environmental needs.

4. Laboratories and Research Institutions: Safely dispose of laboratory animal remains and related biological waste, adhering to strict biosafety regulations.

5. Zoos and Wildlife Sanctuaries: Handle the remains of large or potentially biohazardous animals to ensure public health and safety.

Why Choose Us?

1. Ultimate Environmental Protection, Worry-Free Compliance

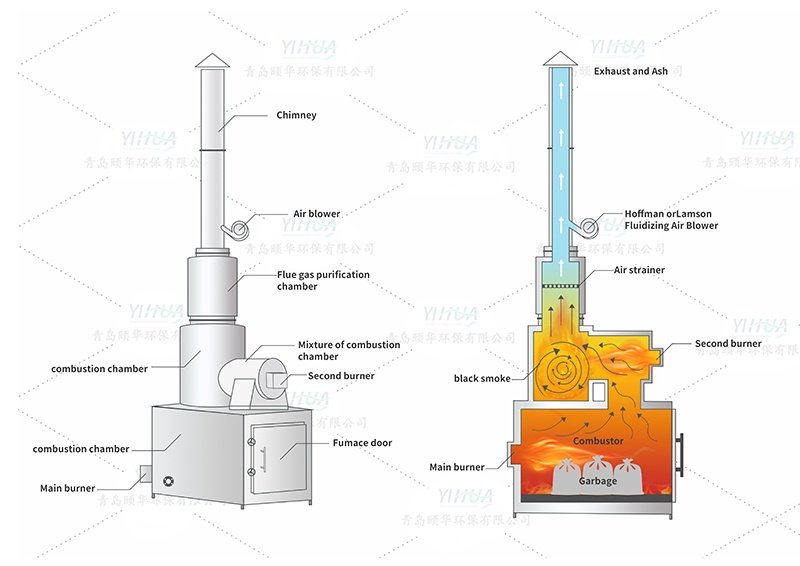

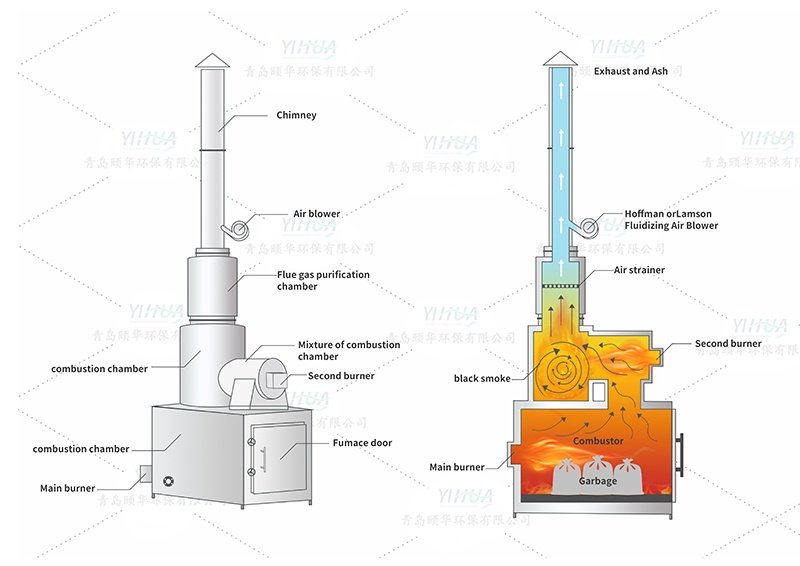

Dual Combustion Technology: Utilizing a primary combustion chamber + secondary combustion chamber design, flue gas is thoroughly decomposed at high temperatures, effectively suppressing the formation of harmful substances such as dioxins.

High-Efficiency Flue Gas Treatment System: Built-in professional-grade dust removal, deacidification, and adsorption devices ensure emissions are far below the most stringent international environmental standards, such as EU 2010、75、EU.

Odor-Free: Fully enclosed operation eliminates unpleasant odors during the treatment process, protecting the surrounding environment.

2. High Efficiency and Energy Saving, Lowering Costs

Fast Ignition and Temperature Rise: Optimized burner design and furnace insulation enable rapid reaching of operating temperature, significantly shortening treatment cycles and saving fuel costs.

Excellent Thermal Efficiency: A scientific furnace structure ensures full utilization of heat, reducing energy consumption by up to 30% compared to traditional equipment.

Automated Operation: A PLC intelligent control system enables one-touch start and stop, automatic temperature control, and fault diagnosis, reducing manual intervention and improving operational efficiency.

3. Durable, Safe, and Reliable

Military-grade materials: The furnace body is constructed of high-temperature, corrosion-resistant stainless steel and refractory materials, ensuring a long service life despite prolonged high temperatures.

Comprehensive safety features: Multiple safety interlocks, including over-temperature alarms, flameout protection, and abnormal pressure alarms, ensure operator and equipment safety.

User-friendly design: The optimally sized and accessible loading door facilitates the loading of animal remains of various sizes while effectively reducing operator workload.

Our Animal Incinerator follows a precise, controlled thermal decomposition process, which can be simplified into three core stages:

Stage 1: Primary Combustion - Main Combustion Chamber

Animal remains are fed into the main combustion chamber via a dedicated feed system. High-efficiency burners rapidly raise the chamber temperature to a stable 800-900°C. At these high temperatures, organic matter (including pathogens, viruses, and bacteria) is completely decomposed and burned.

Stage 2: Gas Recombustion - Secondary Combustion Chamber

The high-temperature flue gas produced by the primary combustion still contains a small amount of incompletely burned combustible gases and particulates. This flue gas is forced into a separate secondary combustion chamber. Auxiliary burners raise the chamber temperature to over 1100°C for a secondary combustion process lasting at least two seconds. This step is critical for completely destroying harmful substances and eliminating black smoke and odor.

Stage 3: Flue Gas Purification and Exhaust

The clean, high-temperature gas after complete combustion can be processed through a custom flue gas treatment system. The system effectively removes dust, acidic gases, and heavy metal residues from flue gas, ultimately releasing clean, colorless, and odorless flue gas that meets standards safely into the atmosphere through the chimney. All that remains is a small amount of sterile, odorless, and pure white ashes.

Name | YHIA-50 | YHIA-100 | YHIA-200 | YHIA-300 | YHIA-500 |

Dimensions | 1400*1000*2100mm | 1500*1100*2200mm | 2000*1300*2600mm | 2500*1400*2400mm | 2900*1800*2800mm |

Garbage entrance size | 1100*500*500mm | 1200*600*500mm | 1400*800*700mm | 1800*900*900mm | 2300*1200*900mm |

Incineration capacity | 30~50kg/h | 80~100kg/h | 150~200kg/h | 300~400kg/h | 500~600kg/h |

Induced draft fan | 0.75KW | 0.75KW | 0.75KW | 3 KW | 3 KW |

Burner | 2 sets | 3sets |

Voltage | 220V/380V |

Fuel | Diesel fuel |

Fuel consumption per hour | 4~6L/H | 5~8 L/h | 20~30 L/h | ~40 L/H | 30~40 L/H |

Total power | 1.5KW | 1.5KW | 1.8KW | 4 KW | 4 KW |

Feeding method | manual |

Ignition method | automatic |

Incineration temperature | Main combustion chamber 600~800 degrees, secondary combustion chamber 900~1100 degrees |

Floor space | 2.5*3m | 2.5*3m | 4*6m | 5*3m | 6*4m |

Material | Shell: Welded steel plate. Firewall: monolithic prefabrication of refractory bricks and refractory concrete |

Chimney | 3m | 6m |

Weight | 2100kg | 2500kg | 3200kg | 4600kg | 6500kg |